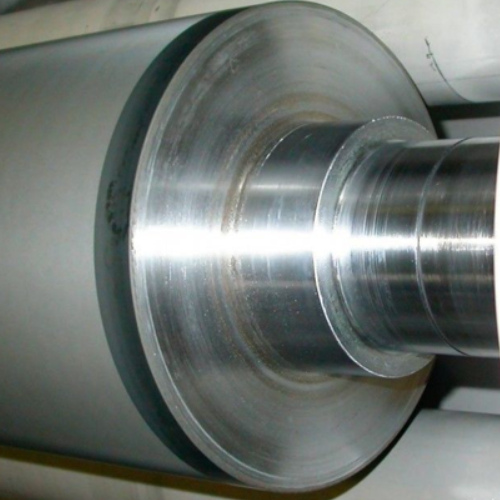

Keeping your anilox rolls clean is critical to print quality, productivity and roller lifespan. At Future Chemicals, we provide industry-grade ultrasonic and manual anilox cleaning solutions, trusted by print professionals across the UK and Europe.

Anilox rolls accumulate residue over time based on the type of ink used in your print environment:

Over 20 businesses in the UK rely on Sonic Kleen to maintain their anilox rolls. Join them in choosing a proven solution that works.

Ink Kleen is specifically formulated for removing water-based ink from anilox rollers, press frames, and ink pans. It can be used manually or in immersion systems.

Use UV Wash – it’s designed to dissolve cured UV ink and can be applied by spray, wipe or used in ultrasonic tanks for off-press cleaning.

Sonic Kleen is our dedicated ultrasonic tank solution. It penetrates tight spaces and cleans complex machine components effectively without manual scrubbing.

Yes, all three cleaners — Ink Kleen, UV Wash and Sonic Kleen – are safe for use on ceramic and chrome anilox rollers when diluted and used as directed.

Yes. All three products are immersion tank compatible, with Sonic Kleen being particularly effective in ultrasonic environments, and UV Wash and Ink Kleen performing well in static immersion setups.

Yes, we offer 5L and 25L containers for all cleaning products. Contact us directly for volume pricing or sample requests.

Dilution is dependent on the extent of the cleaning required. All solutions can be diluted and depends on the cleaning task and level of residue. Dilution guides are provided on the label and data sheets.

Absolutely. We offer free samples for businesses to trial. Click here to request one or simply fill in our sample request form.

© 2025 Future Chemicals Solutions. All rights reserved.

Address: 55 Crown St, Brentwood CM14 4BD, United Kingdom